Medical & Pharma

FRANKLIN AUTOMATION designs and qualifies medical device assembly machines that meet the strict requirements of the medical sector. Full documentation is provided with the machine and FRANKLIN develops detailed protocols to run the acceptance tests (FAT, SAT). Assembly and testing precision is guaranteed while maintaining high speeds in a clean environment.

Medical devices must be used safely, so to ensure highest levels of quality our machines include 100% compliance inspection of parts online.

FRANKLIN AUTOMATION also develops prototyping, de-risking and pilot machine phases.

Examples of assembled MEDICAL Devices automated by FRANKLIN AUTOMATION and the NEYRET GROUP include:

Safety syringe

Needle protection system

Veterinary syringe

Prefilled syringe

Injection site without needles

Plastic syringe

Syringe filter

Artificial kidney

Morphine pump

Oral suction valve

Oral foam swab

Homeopathic dosing tube

Single-dose homeopathic tube

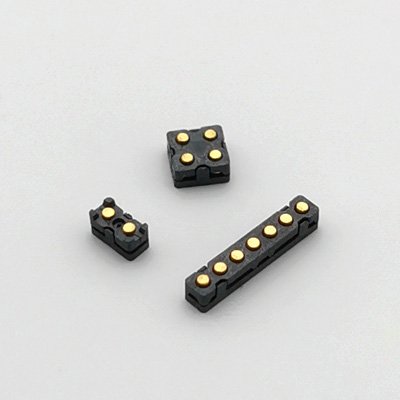

Pacemaker battery contact

Dosimeter

Disposable Pressure Gauge

Unit diagnostic tests (VIDAS)

Vial Adaptor Reconstitution with Needle Protection

Dosing valve for aerosols and sprays

Nasal spray

Bi-dose nasal spray

MDI metered dose inhaler

Powder inhaler

Insulin pen

Special medical injector

Pen cap

Self-prick device

Safety lancet