Electrical and Connectors

Assembly lines for complex electrical products.

Franklin Automation has deep experience with the assembly and testing of electrical components including circuit separation, insert mold component feeding, resistance welding, high pot and continuity testing and finally tray packing and palletizing.

The expertise of Societe GUY NEYRET makes it possible to create complete assembly lines of very complex electrical products. We master specific processes related to the handling, cutting and assembly of metal components. We integrate braid compaction, metal or US laser welding, laser marking, traceability. All operations are carried out with great precision and electrical tests are carried out on critical components to ensure their compliance and safety in their daily use. The automation of the assembly process excludes human error at all stages and guarantees process repeatability. For fragile components the assembly line can include de-palletizers and tray palletizers.

Examples of assembled electrical and connector products include:

Airplane Connector

Riveted Automotive Connector

Circuit Breaker

Disconnector

Electromagnetic Relay

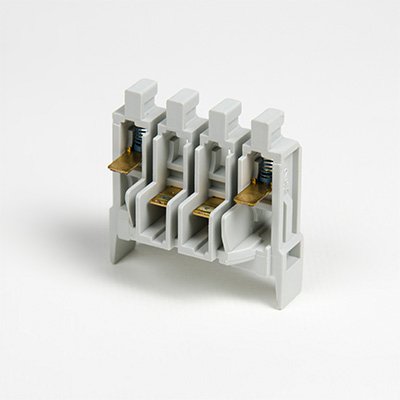

Fuses

Halogen Lamps

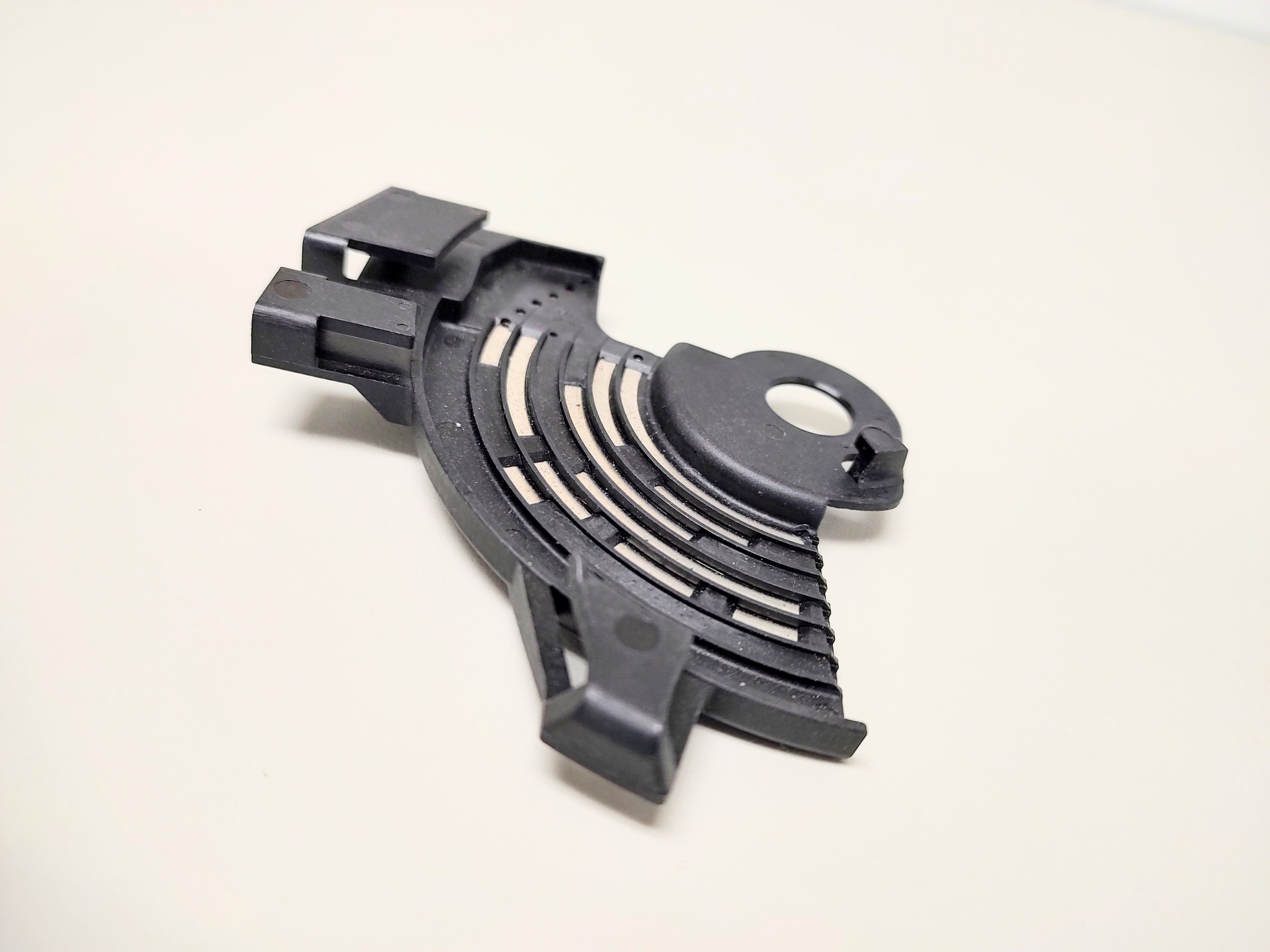

Over-Molded Automotive Connector

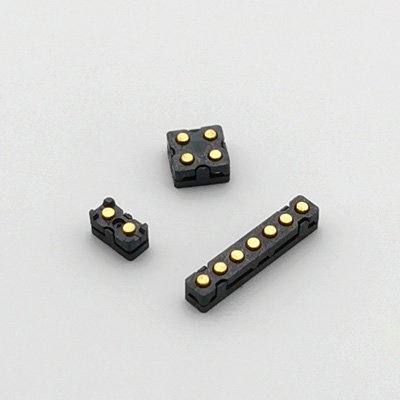

Pacemaker Battery Contacts

Power Canalis

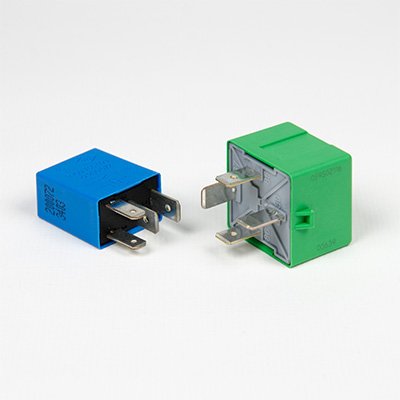

Power Relays

20-40A Relays

RJ45 Outlets

Socket-Outlets with Child Safety